When I was starting out with column drills, I discovered all of the terms for the various parts and measurements really confusing. This post is designed to help you if you are trying to choose a drill and have to comprehend just what all the terminology and also jargon means.

Parts Found on Pillar Drills

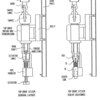

Drill head-- the assembly that comprises the chuck, pin, drill bit, electric motor as well as wheels.

Base-- the hefty "foot" of the machine that is bolted to the flooring in the case of a larger pillar drill or the workbench in the case of a smaller sized bench-mounted drill.

Column-- this is the vertical column that gives the column drill among its names (confusingly, its various other common names are "bench drill" and also "drill press").

Spindle-- the vertical axle that is in line with the drill bit as well as connects the chuck to the drill head.

Chuck-- the assembly that fits into the pin and also holds the drill bit.

Table-- this is in some cases bit greater than a step in smaller sized bench drill versions. It's the support for the job piece to be pierced, as well as is connected to the column some range below the head and over the base. Tables can be rectangular or round, as well as some can be tilted to allow tilted exploration with a job piece. Column drill accessories can be bought to clamp or cradle work pieces in numerous angles.

Deepness gauge-- a setting that enables the bench drill to pierce an opening part-way via a work item.

The Meaning of Dimensions in Drill Specifications

Throat range-- this is the dimension from the local side of the pillar to the spindle centre.

Swing-- this is a common measure of the ability of pillar drills as well as is specified as two times the throat distance, or to place it an additional method, the optimum dimension of disc in which you can drill a main hole.

Spindle taper-- this specifies the shape of the end of the spindle. There are long, brief, female as well as male types. The chuck needs to be compatible with the pin taper.

Collar Size-- this is the external diameter of the collar or chuck setting up that holds the little bit.

Chuck size-- this is the diameter of the inner opening of the chuck assembly, so it specifies the optimum dimension of bit stem that the drill could take. As a result of this it is likewise recognized merely as the drilling capacity.

Pin travel-- this is the amount through which the spindle can be decreased or increased vertically and also specifies the maximum deepness of opening you could pierce in one pass.

Maximum distance spindle-to-table-- this distance defines the deepest job piece that you can get onto the table.

Optimum range spindle-to-base-- this resembles the above and specifies the optimum depth of work piece you could drill with the table removed. For More Information visit http://www.drawworkslp.com/volant-crt/